Wilo Nordic AB

Box 3024

350 33 Växjö

Besöksadress:

Isbjörnsvägen 6

352 45 Växjö

Öppettider:

Mån-Tor: 07.00-16.30

Fre:07.00-15.30

Tel: +46 470 72 76 00

www.wilo.se

Digitala verktyg

Utbyte och dimensionering av pumpar

Wilo-Pumplotsen

Hitta rätt ersättningspump och ta del av nyttig utbytesinformation.

Wilo-Select

Pumpdimensionering och framställan av LCC- och amorteringskalyler.

Wilo-Quick-Select

Förenklat dimensioneringsprogram för våta cirkulationspumpar.

Dokumentation och CAD-/BIM-filer

Wilo-Online-katalog

Produktdata, pumpkurvor, produktbeskrivningar, dokumentation mm.

PDF-bibliotek

Här hittar du broschyrer, kataloger och prislistor i pdf-format.

Wilo-BIM- och CAD-katalog

Ladda hem önskat filformat via Cadenas eller Wilos databas.

Egen vattenförsörjning och branschportal

Wilo-Eget vatten

Allt du behöver veta om pumpar och pumpsystem för egen vattenförsörjning.

RSK-databasen

Sök Wilo-produkt för produktdata eller hemladdning av kopplade dokument.

Övriga verktyg

Här hittar du bl a enhetskonverterare, felmeddelande-assistent mm.

Prislista Sverige - februari 2024

Prislista februari2024. Pumpar och tillbehör för cirkulation, kallvatten och avlopp. Pumpar, pumpsystem och tillbehör för byggteknik, industriella- och kommunala applikationer.

Nyheter

16 apr. 2024

Wilo-Select 5 online tillgänglig online

Översikt av alla nyheter

5 apr. 2024

Välkommen att besöka oss på Nordbygg 23-26 april

Den 23-26 april är det då åter dags för Nordens största bygg- och VVS-mässa.

5 mars 2024

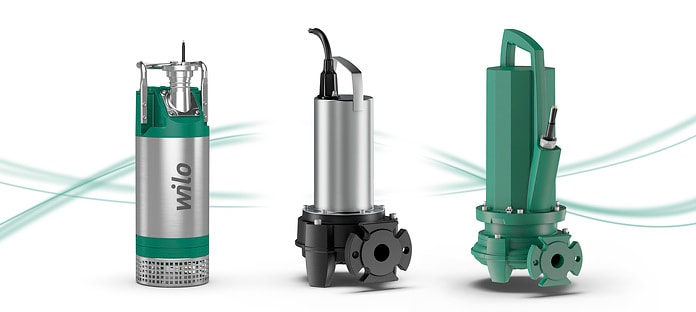

Padus och Rexa-pumpar från Wilo – “Simply safer”

Dränerings- och avloppspumpar för fastighet och tomt